Polyester Resin Plant

Product Details:

Polyester Resin Plant Price And Quantity

- 6000000 INR/Unit

- 1 Unit

Polyester Resin Plant Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 1 Unit Per Month

- 2 Months

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

A polyester resin plant is a facility that manufactures polyester resin, a versatile liquid material used in various applications, including:

Composite materials: Polyester resin is a key component of fiberglass composites, commonly used in boat hulls, building panels, and automotive parts.

Coatings: Polyester resins are used in paints, varnishes, and gelcoats for their durability, gloss, and weather resistance.

Adhesives: Polyester resins can be used as adhesives for bonding various materials, such as wood, metal, and concrete.

Casting: Polyester resins can be used for casting decorative objects, countertops, and other functional parts.

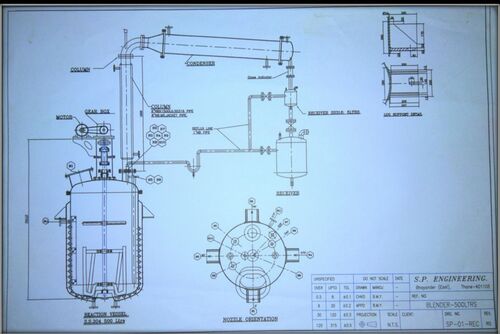

The exact configuration of a polyester resin plant can vary depending on the desired production capacity, resin type, and level of automation. However, a typical plant will involve the following key stages:

Raw material storage: This includes tanks for storing the liquid monomers (such as maleic anhydride and propylene glycol) and other chemicals used in the resin production process.

Esterification: The monomers are reacted in heated kettles with a catalyst to form the polyester resin precursor.

Blending: The resin precursor is blended with additives and solvents to achieve the desired properties, such as viscosity, flexibility, and curing speed.

Filtration and storage: The finished resin is filtered to remove impurities and then stored in tanks until needed.

Packaging: The resin is packaged in drums, totes, or bulk containers for shipment to customers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese