उत्पाद विवरण:

- मशीन का प्रकार Resin Reacting Plant

- विशेषताएँ Explosion Proof, Corrosion Resistant, Agitator with VFD, Full Vacuum Capability

- फ़्रिक्वेंसी 50/60 Hz

- पावर रेटिंग Data Not Available (refer to Power specification)

- कंट्रोल सिस्टम

- परिचालन तापमान Up to 250°C (reactor vessel specification)

- उत्पादन क्षमता 500–10000 kg/Batch

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

- CE Mark / GMP / ASME as per request

- Helical/Anchor/Turbine/Paddle (application-based)

- Top and side manhole with sight glass

- Fully automatic, semi-automatic, or manual options

- Chilled water, cooling tower, compressed air, and process steam as per process needs

- SS316/SS304 piping with TC end connections

- Yes – Provided with all reactors

- Bottom flush type/Fully openable for easy cleaning

- 6–12 hours per batch (standard, as per resin type)

- Temperature, Pressure, and Level sensors with digital display

- SS304/SS316/Mild Steel with Internal Lining (as per chemical compatibility)

- Installation, commissioning, operator training, and annual maintenance contracts available

- Over-pressure safety valve, pressure gauge, flameproof electricals, emergency shutdown system

- 1 to 4 (Custom solution available)

- Full vacuum or partial vacuum up to -760 mmHg

- Thermic Fluid Heater / Steam / Electrical Heating options

उत्पाद की विशेषताएं

- External water-cooled condenser, reactor jacket cooling

- Direct/Reduction Gear Motor

- Analog & Digital I/O, RS485, Ethernet (for SCADA integration)

- Polyester Resin

- 380–440 V

- Grease lubricated mechanical seals (if applicable)

- Silver/Grey (standard), others on request

- 25-75 kW (depending on plant capacity and configuration)

- 7.5-22 kW (dependent on reactor volume)

- Atmospheric to 3 kg/cm² (customizable as per process requirements)

- 5000 – 28000 kg (varies with size and configuration)

- Resin Reacting Plant

- Explosion Proof, Corrosion Resistant, Agitator with VFD, Full Vacuum Capability

- 50/60 Hz

- Data Not Available (refer to Power specification)

- Up to 250°C (reactor vessel specification)

- 500–10000 kg/Batch

- Customized as per plant size – commonly 6m x 4m x 5m

- Production of Unsaturated Polyester Resin for FRP, casting, coatings, adhesives, and composites

- PRP-XXXX (Customized Model Number)

- Skid Mounted/Structural Frame

- ±1% process parameter tolerance

- <85 dB(A)

- CE Mark / GMP / ASME as per request

- Helical/Anchor/Turbine/Paddle (application-based)

- Top and side manhole with sight glass

- Fully automatic, semi-automatic, or manual options

- Chilled water, cooling tower, compressed air, and process steam as per process needs

- SS316/SS304 piping with TC end connections

- Yes – Provided with all reactors

- Bottom flush type/Fully openable for easy cleaning

- 6–12 hours per batch (standard, as per resin type)

- Temperature, Pressure, and Level sensors with digital display

- SS304/SS316/Mild Steel with Internal Lining (as per chemical compatibility)

- Installation, commissioning, operator training, and annual maintenance contracts available

- Over-pressure safety valve, pressure gauge, flameproof electricals, emergency shutdown system

- 1 to 4 (Custom solution available)

- Full vacuum or partial vacuum up to -760 mmHg

- Thermic Fluid Heater / Steam / Electrical Heating options

व्यापार सूचना

- ,

- प्रति महीने

- महीने

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

उत्पाद वर्णन

A polyester resin plant is a facility that manufactures polyester resin, a versatile liquid material used in various applications, including:

Composite materials: Polyester resin is a key component of fiberglass composites, commonly used in boat hulls, building panels, and automotive parts.

Coatings: Polyester resins are used in paints, varnishes, and gelcoats for their durability, gloss, and weather resistance.

Adhesives: Polyester resins can be used as adhesives for bonding various materials, such as wood, metal, and concrete.

Casting: Polyester resins can be used for casting decorative objects, countertops, and other functional parts.

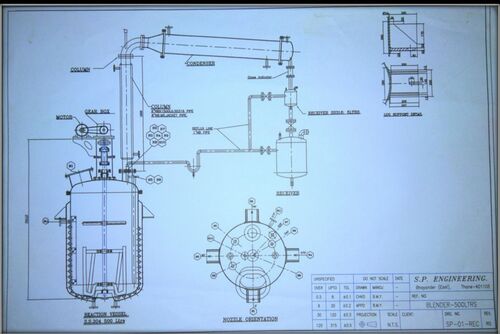

The exact configuration of a polyester resin plant can vary depending on the desired production capacity, resin type, and level of automation. However, a typical plant will involve the following key stages:

Raw material storage: This includes tanks for storing the liquid monomers (such as maleic anhydride and propylene glycol) and other chemicals used in the resin production process.

Esterification: The monomers are reacted in heated kettles with a catalyst to form the polyester resin precursor.

Blending: The resin precursor is blended with additives and solvents to achieve the desired properties, such as viscosity, flexibility, and curing speed.

Filtration and storage: The finished resin is filtered to remove impurities and then stored in tanks until needed.

Packaging: The resin is packaged in drums, totes, or bulk containers for shipment to customers.

Versatile Construction & Agitation

Reactors are crafted from SS304, SS316, or Mild Steel, featuring internal linings compatible with various chemicals. Multiple agitator types-helical, anchor, turbine, or paddle-are selectable as per your process requirements, ensuring optimal resin mixing and consistency. This adaptability enhances performance for diverse resin applications.

Advanced Automation & Safety

With PLC-based control systems that can be set to automatic, semi-automatic, or manual, operators enjoy precision management of temperature, pressure, and levels via digital instrumentation. Integrated safety measures include over-pressure valves, flameproof electricals, and emergency shutdown systems for secure and reliable plant operations.

Customizable Production Solutions

The plant can accommodate 1 to 4 reactors, with batch capacities ranging from 500 kg to 10,000 kg. Each reactor is equipped for easy cleaning-featuring bottom flush or fully openable discharge valves, top and side manholes, and sampling ports-facilitating flexible, high-throughput production tailored to client needs.

FAQ's of Polyester Resin Plant:

Q: How is the Polyester Resin Plant customized to suit different production requirements?

A: Each plant is designed to client specifications, including reactor material (SS304, SS316, or Mild Steel), internal linings for chemical compatibility, number of reactors (1-4), and dimensions. Agitator type, batch capacity, automation level, and compliance certifications (CE, GMP, ASME) are fully customizable to meet specific resin applications and output needs.Q: What safety features are integrated into the plant's design?

A: The Polyester Resin Plant includes comprehensive safety provisions like over-pressure safety valves, emergency shutdown systems, flameproof electrical components, pressure gauges, and digital process monitoring. These features safeguard operators and equipment throughout continuous or batch production processes.Q: When is full vacuum capability or partial vacuum applied in the plant operation?

A: Full or partial vacuum (up to -760 mmHg) is utilized where process requirements demand controlled atmospheric conditions inside the reactor, enhancing resin quality and preventing unwanted reactions. The vacuum settings depend on the type of polyester resin being produced and specific processing protocols.Q: Where can this plant be installed, and what utilities are required?

A: Suitable for installation in industrial manufacturing environments, the plant requires utilities such as chilled water, process steam, compressed air, and cooling tower water. It runs on electric power (25-75 kW, 380-440 V, 50/60 Hz), with space and support infrastructure tailored to the plant's custom dimensions.Q: What is the standard process duration and how is batch timing managed?

A: Each resin batch typically completes within 6-12 hours, depending on the resin type and process parameters. The advanced PLC-based automation system enables precise control and monitoring of batch timings, process temperature, pressure, and mixing to ensure consistent, repeatable outcomes.Q: How does the plant benefit resin manufacturers?

A: Manufacturers benefit from robust construction, corrosion resistance, customizable automation, and safety-centric design. The plant's flexibility enhances production efficiency, reduces downtime due to easy cleaning and maintenance, and delivers precise process control for high-quality resin output.Q: What after-sales support and services are provided?

A: Comprehensive after-sales support includes installation, commissioning, operator training, and annual maintenance contracts. Technical assistance and spare parts are readily available through a reliable service network serving distributors, exporters, manufacturers, suppliers, and traders in India and beyond.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese