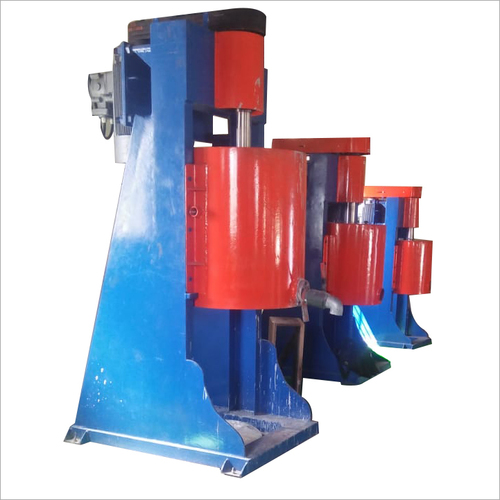

Batch Type Bead Mill

Product Details:

- Type Batch Type Bead Mill

- Material Stainless Steel

- Capacity 5 to 200 Liters

- Computerized No

- Automatic Grade Automatic

- Control System PLC Based

- Drive Type Electric

- Click to View more

Batch Type Bead Mill Price And Quantity

- 200000.00 - 1000000.00 INR/Unit

- 1 Unit

Batch Type Bead Mill Product Specifications

- No

- Approx. 250-1500 kg

- 5 HP - 50 HP

- Stainless Steel

- PLC Based

- Variable (As per Model)

- Batch Type Bead Mill

- Automatic

- Electric

- 415 V

- 5 to 200 Liters

- Multi (Blue/White/Grey as per design)

Batch Type Bead Mill Trade Information

- 50 Unit Per Month

- 1-2 Months

Product Description

Our proficiency in this developing industry enables us to manufacture, export and supply a broad assortment of Batch Type Bead Mill. The offered machine is precisely manufactured with the implementation of the contemporary technology and premium quality components under the instruction of our adept professionals. This machine is globally utilized for the purpose of grinding. Furthermore, this Batch Type Bead Mill is made to pass through stringent examining process to assure its high production capacity.

Features:

-

Need less maintenance

-

Easy to operate

-

Hassle-free working

-

Less power consumption

Batch Type Bead Mill

We are manufacturing Batch Type Bead Mill.

Capacity- 1 Liter To 500 Liters

Superior Fineness and Versatility

Achieve particle sizes below 5 microns with precision. The batch type bead mill is designed for various industries including paints, inks, dyes, agrochemicals, and pharmaceuticals. Its adaptability to different grinding mediaceramic, glass, or zirconiummakes it suitable for a diverse range of formulations and processes.

Built for Efficiency and Safety

With a maximum chamber volume of 260 liters and a throughput of 500 LPH, this mill optimizes production for both small and large batches. Integrated overload protection and emergency stop provide enhanced operational safety, while the PLC-based control system ensures smooth, automated processing for consistent results.

FAQs of Batch Type Bead Mill:

Q: How does the batch type bead mill achieve fine particle sizes under 5 microns?

A: The batch type bead mill uses high-energy pin or disc rotors in a jacketed chamber, combined with small-sized grinding media (0.1 mm to 2.5 mm), to break down particles to below 5 microns. Continuous circulation and intensive agitation increase contact between beads and product, resulting in exceptional fineness.Q: What is the process for loading and discharging material in this bead mill?

A: Material is fed into the milling chamber in a batch process. After grinding, mechanical separation technology efficiently discharges the finished product, separating it from the grinding media for easy collection and cleaning, streamlining workflow.Q: When should the water cooling system be used?

A: The jacketed chamber should be used with water cooling during milling operations where temperature control is critical, such as with heat-sensitive products or when processing large volumes, to ensure consistent particle size and prevent degradation.Q: Where can the batch type bead mill be applied?

A: This bead mill is suitable for industries such as paint, ink, pigment, dye, agrochemical, and pharmaceuticals, where achieving ultra-fine dispersions and homogeneous blends is essential. It is particularly beneficial for applications requiring particle sizes below 5 microns.Q: What are the benefits of using ceramic, glass, or zirconium beads as grinding media?

A: Using ceramic, glass, or zirconium beads offers high durability, chemical resistance, and efficient energy transfer during milling. Choosing the appropriate bead material ensures low contamination, high grinding efficiency, and longer operating life for both beads and equipment.Q: How does the PLC-based control system enhance mill operation?

A: The PLC-based system automates key operational parameters, such as rotor speed, batch timing, and safety checks, ensuring consistent product quality, reducing manual intervention, and improving operational reliability.Q: What maintenance is required for the batch type bead mill?

A: The stainless steel construction and robust design ensure low maintenance. Routine checks on the grinding media, seals, and cooling system are recommended, along with periodic cleaning of the milling chamber and mechanical separator to maintain peak performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese